Hand Carved Tap Handles

/DC has had some impressive/ridiculous storms this summer and because of them a tree fell down in our neighborhood. It took someone a few days to clear it from the bike path it fell on, but when they did they cut the branches into logs which they piled neatly next to the path. I like to build things, but generally when woodworking I can't find the greatest wood around here. After a bit of google-fu I am fairly certain it is some type of Ash tree. I took a log home and started working on Lisa's birthday presents.

Here is where it started: back yard, hatchet, log. I didn't know it was Ash at first, it was just ridiculously hard wood.

After taking off the bark and a bit of sap wood, I wanted to dry it out a bit since it was so green and wet. I think I baked it at about 190 for a few hours. If I wasn't trying to have it done in a weekend, I would have let it sit for a few more weeks. I turned off the oven and let it cool over night.

I have no idea how long it took to get to this point. Most of the work was done with the hatchet, before I started to finalize the shape with a hand saw.

The rough first shape

The original plan was just to replace the 3D printed handle we had, but as soon as I had the rough cut I realized it was going to take up too much space. It was so big I could have made two tap handles...

I made two from the rough cut

They clean up well after a bit of sanding. The biggest difficulty was finding an insert to connect it to the tap. Made an absurd number of trips to hardware stores. The local family owned hardware store had dual threaded taps, that were the wrong threads per inch(TPI). Conceding my defeat of finding them locally (local homebrew store may have had them but were closed) I ordered them on amazon. I was all up in arms that they were four dollars a piece! Then I got a package two days later:

Instead of ordering four inserts like I thought, I got 40. Instantly all anger gone since it was just too funny. I guess I will be making more tap handles in the future now.

For reference: Internal threads are 3/8" with 16 UNC/TPI or anything that is threaded for 3/8" coarse should fit on a tap. The external threads are about 1/2" 13 UNC, instructions will say to drill a 1/2" wide 3/4" deep hole to screw these in. Which might work for softer wood. For hard wood you will need to drill a 9/16" hole. I had to buy a new bit for it since I couldn't use a spade bit by hand.

All thats left was to paint and finish the wood. The face of them we used a chalkboard paint and the rest of the wood was finished with tung oil.

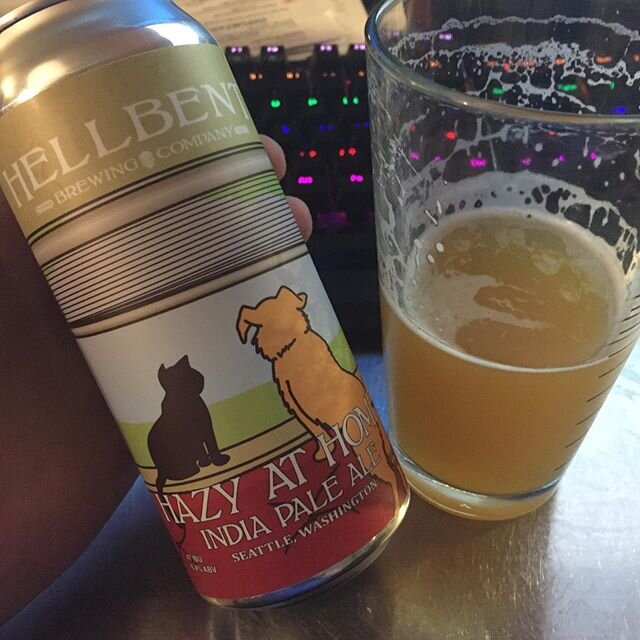

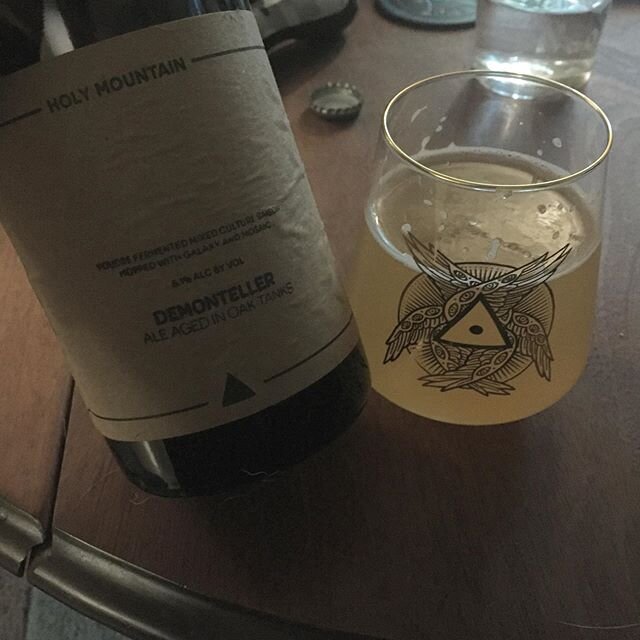

Here they are in use

I think they turned out well. Now I just need a lathe to turn the other half of the log I have left over.

Happy Birthday Lisa!